About us

Welcome to YOKE in Europe

For more than 40 years, YOKE has pursued a clear philosophy as one of the leading manufacturers of lifting and rigging equipment: “Safety is our first priority.” This commitment is the standard that guides everything we do. From development to production to delivery, safety and quality always come first. With more than 3,500 certified products, we not only meet the highest international standards, we actively set new benchmarks for smart lifting technology designed for maximum safety.

In Europe, YOKE combines the strength of a global technology leader with the experience and customer proximity of local partners. Our roots in Germany, for example, go back to 2001, when Ostalbketten was founded as a specialist for lifting accessories. Today, we stand for highly available certified products, digital innovation, and personal support. If you are looking for safe, innovative, compliant, and efficient lifting solutions, you have come to the right place.

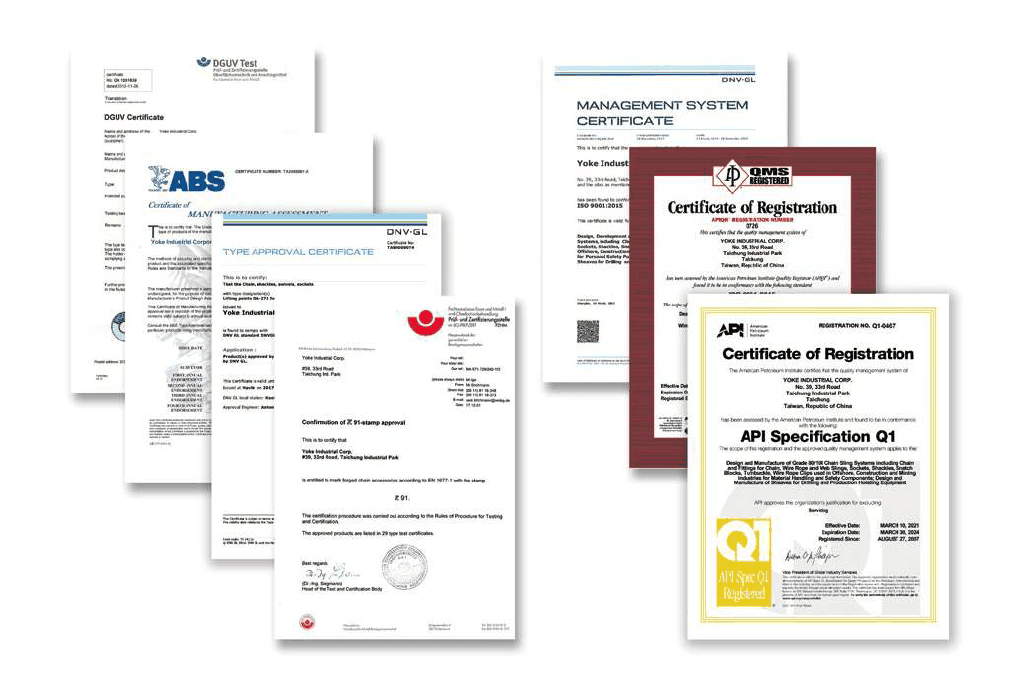

Quality down to the smallest detail

At YOKE, quality is not a promise, it is a lived reality. It begins with the careful selection of materials that meet the highest industrial requirements in terms of strength, corrosion resistance, and durability. Our planning and production processes follow precisely defined procedures that comply with globally recognized standards. We rely on state-of-the-art machining technologies and high-precision equipment to guarantee consistently superior product quality.

What sets YOKE apart is uncompromising quality assurance. Every single component undergoes 100% crack testing before delivery. Our in-house laboratories analyze material behavior, load capacity, and microstructures. At the same time, our digital RFID solutions ensure that all production data is documented, traceable, and accessible at any time. This process is further supported by rigorous automation, ensuring consistent excellence while increasing efficiency. This is how genuine YOKE safety is created: through technical precision, systematic control and transparent documentation.

Smart lifting technology that thinks ahead

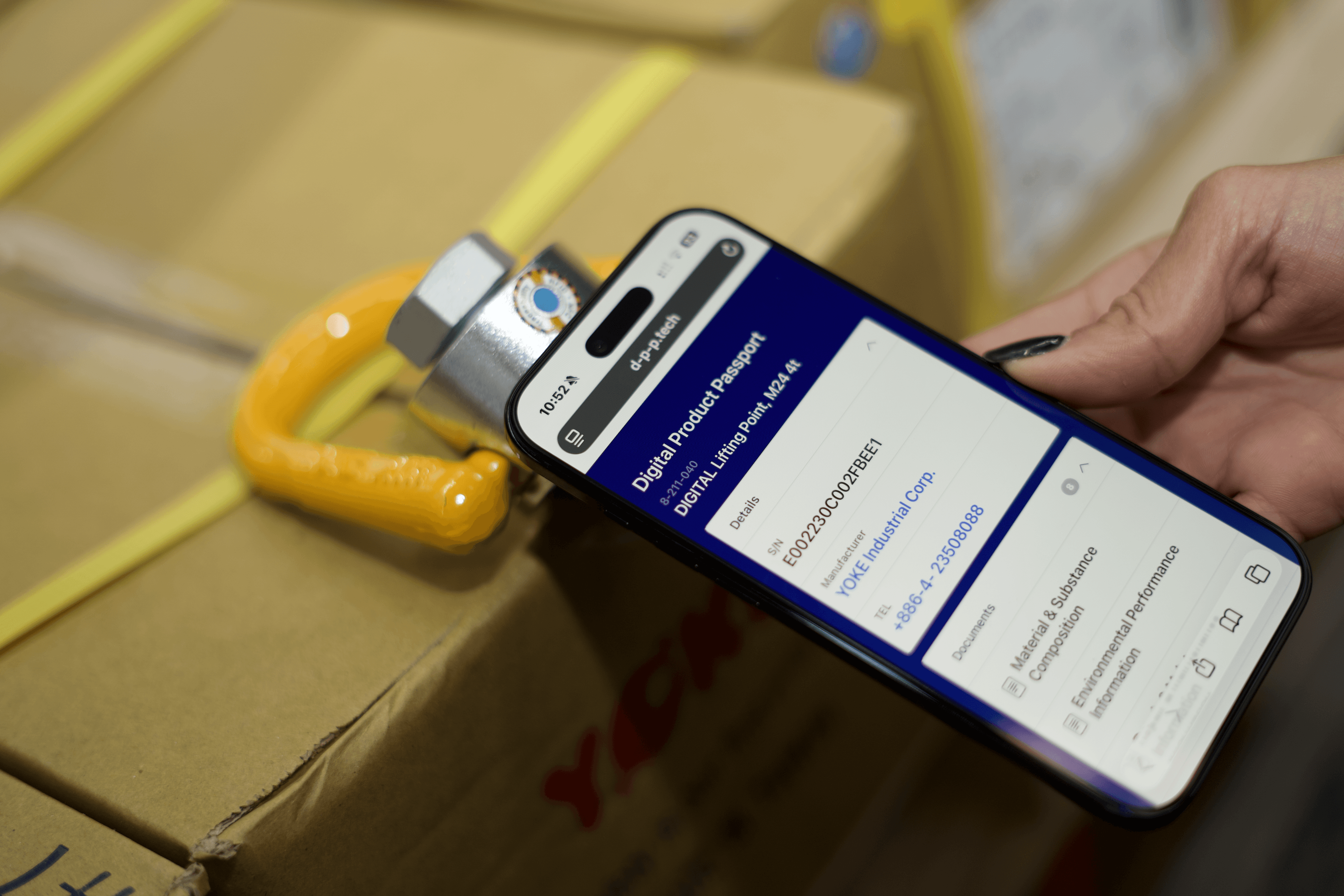

At YOKE, innovation is not only reflected in new products but also in a clear commitment to digitalization. As the first manufacturer worldwide, we have equipped almost our entire product range with RFID technology. Our RFID tags, the exceptionally robust BlueSupra series, make every component uniquely identifiable and open up completely new possibilities for managing, inspecting and maintaining lifting equipment.

With the introduction of the industry’s first Digital Product Passport (DPP) in accordance with the ESPR regulation, we responded early to upcoming requirements and created a system that goes far beyond compliance. The DPP not only enables seamless traceability but also supports sustainability, efficiency, and legal certainty. Our customers benefit directly: they work more safely, meet standards more easily, and save time in daily operations.

The DPP also offers a unique advantage for customers operating in the world’s most demanding environments, including aerospace, defense, oil & gas, wind energy, mining, and heavy industry. In these high-risk sectors with strict OSHA and QHSE requirements, our technology delivers unprecedented transparency and control across the entire lifecycle of critical assets.

Europe-wide delivery promise

What good is the best product if it isn’t available when you need it? That’s exactly why YOKE operates a high-performance central warehouse in Southern Germany, designed to stock the entire YOKE product range locally for the European market. We deliver anywhere in Europe within 24 to 48 hours, reliably, predictably, and with full transparency. This service isn’t a luxury; it’s our standard.

Our ability to offer this level of reliability comes from the combination of tradition and innovation. Our European presence traces back to Ostalbketten in Aalen, Baden-Württemberg, a company with deep regional roots that today, under the YOKE name, unfolds its full potential. For our customers, this means: international quality paired with the service culture of an experienced, medium-sized partner.

Big enough to crush it. Small enough to care.

YOKE is large enough to set global standards in the industry, yet we always make sure to treat every customer with the same level of personal attention. Or, as our President Steven Hong puts it: “Big enough to crush it. Small enough to care.”

The integration of Ostalbketten was a deliberate step toward this goal: we want to be strong exactly where our customers are, with familiar contacts, accumulated expertise, and solutions that support them in their daily challenges. To achieve this, we combine the best of both worlds: global innovative strength with more than 500 employees worldwide, our own development and manufacturing, and local proximity with outstanding service and a compelling price-performance ratio.

Responsibility at YOKE

Technological innovation and economic success at YOKE go hand in hand with corporate responsibility. Our ESG strategy is deeply embedded in our day-to-day operations: we digitize processes to reduce paper use and waste, invest in durable, recyclable products, comply with the latest sustainability mandates such as ESPR, and uphold fair labor practices.

We believe that taking responsibility builds trust. That’s why we don’t just create safe products but foster a sense of security: For our customers, partners, and employees.